Industrial

Flooring

Commercial

Flooring

Garage

Flooring

Retail

Flooring

ESD

Flooring

Office

Flooring

Warehouse

Flooring

Gym

Flooring

Factory

Flooring

Product

Range

Our clients

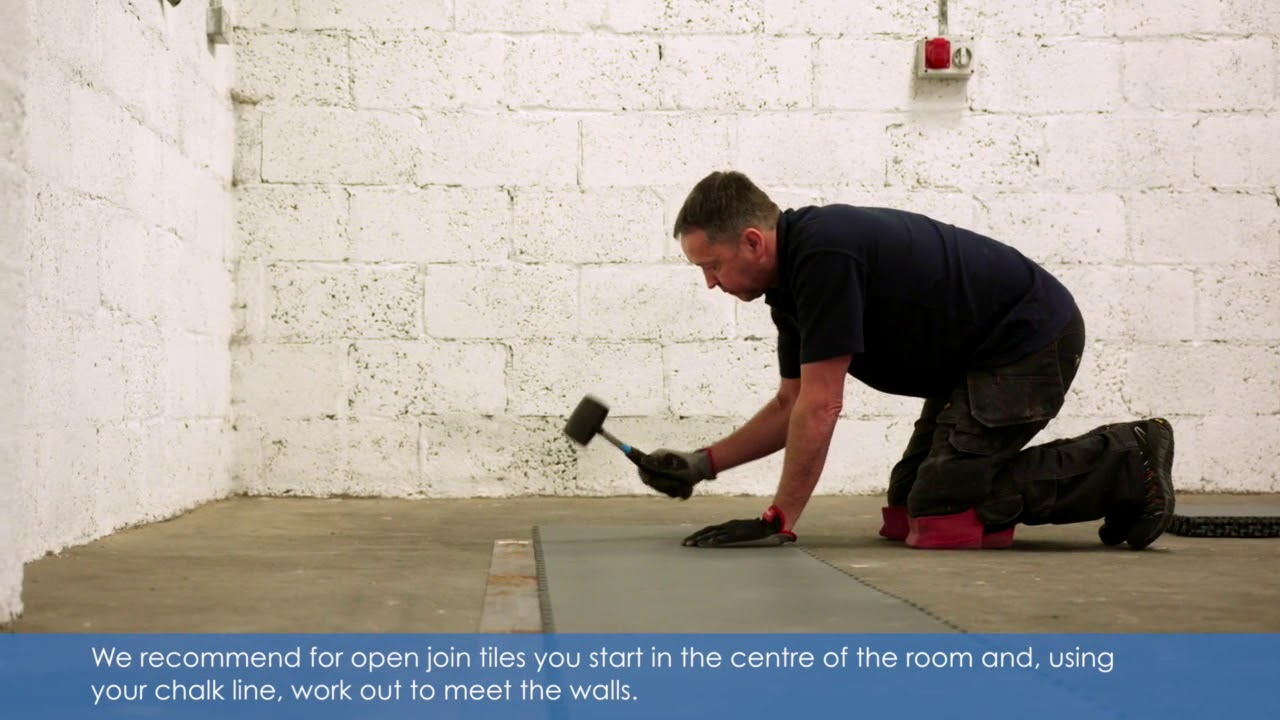

Did We Mention Simple, Speedy Installation?

R-Tek interlocking tiles: Easy Integration and Endless Benefits in any Space. No worries, no stress, no prep and no time is ever wasted on tedious preparation or installation of our premium industrial and commercial floor tiles. With all the benefits of minimal effort and easily installed flooring tiles, R-Tek Manufacturing’s systematic ingenuity relieves any extra headaches that other flooring solutions demand. We prioritise your needs, time and resources to provide the best interlocking tile solution today.

Latest Articles and Guides

Commercial Kitchen Flooring Blog

R-Tile Flooring: A Damp Proof Flooring Solution

ESD vs Anti-Static: What’s the Difference?

How to Clean and Maintain your R-Tile Interlocking Flooring System

Discover why we are leaders in the flooring tile industry for any space

- Best Raw Materials - We pride ourselves in using the best raw materials, with our tiles reducing noise and dust.

- Wide Range of Styles - Outstanding colours and print options, surfaces and textures that boost the look and feel of a space.

- Great for All Industries - Suitable for all and any space – whether commercial, industrial, or residential, our tiles are versatile and ideal.

- Competitive Prices - Our competitive prices never compromise quality and only maximize safety and floor protection, slip resistant and durable.

- Professional Design Collection - Brilliant designer tiles for a sophisticated, clean and polished finish to your environment’s look and feel.

- Strict Quality Assurance -With noteworthy CE accreditation and adhering to ISO 9001 regulations, we are strict about quality assurance and standards.

- Top Results - Care and precision in manufacturing means top results with our leading industrial and commercial tiles.

- Damp Proof - R-Tek industrial flooring and commercial flooring tiles have no damp proof membrane, screed and don’t require adhesives.

- Extra Insulation - For chilly spaces or during colder seasons, get all of the look with twice the comfort – our tiles provided extra insulation.

Still need convincing? See more

Every single tile is produced with precision, care and respect for the environment. Using recycled materials that maintain quality, sustainability and stability, R-Tek Manufacturing offers efficiently generated tile solutions. With various cycles of reuse, our leading methodology means raw materials we use will always serve the purpose with efficiency and with the earth in mind. Reduce your carbon foot print and step into the future with the number one industrial and commercial flooring tile in today’s age. Our powerful manufacturing tools, technology, facilities and team of experts will always consider your safety and that of Mother Nature, hand in hand for a truly innovative solution.

A core element of the R-Tek Manufacturing mission is to maintain excellence in the production and provision of revolutionary tiles and solutions with genuinely crucial benefits for businesses and homes. Why shouldn’t flooring tile installation be simple and straightforward to maximize productivity and time? We think so, and that’s why R-Tek Manufacturing always meets and exceeds expectations of individuals and companies looking for easy cleaning and optimal hygiene. Our simple interlocking floor system blended with sophisticated engineering means zero to minimal downtime for businesses, and less headaches and cleanups at home. Not only can R-Tek tiles be installed in an incredibly short time of just a few hours, but our product also provides great ROI on maintenance expenses, so every minute is a minute gained and every penny spent wisely.

Our customers are our top priority when it comes to the development and maintenance of our industrial standard flooring tiles, generated with expertise and consideration of your needs. Forget hassles of serious cleaning, supplies or heavy-duty equipment, and welcome a remarkable user experience with expert engineered materials. Our cutting-edge machinery empowers our customers with easy control of hygiene, sterility and quick dust removal. Our interlocking flooring tiles provide optimal satisfaction, so grime and dirt become a thing of the past, and a new level of clean is all yours with the R Tile.

We know that research and knowledge with a terrific team work can deliver an outstanding final product. The R-Tek Manufacturing team of experts has developed a methodology and approach to meeting customers’ needs. We offer for a vast range of design options that go hand in hand with practical durability, sustainability and simply outstanding quality flooring tiles. Versatile, easy to mix and match for everything from a chic, to retro and classic look, your R-Tek tiles are hand crafted by our team for extensive lifetime value and style. From our collection of colours, textures, finishes and design edition, we have everything a residential, commercial or industrial space needs to enjoy the advantages of top quality solution.